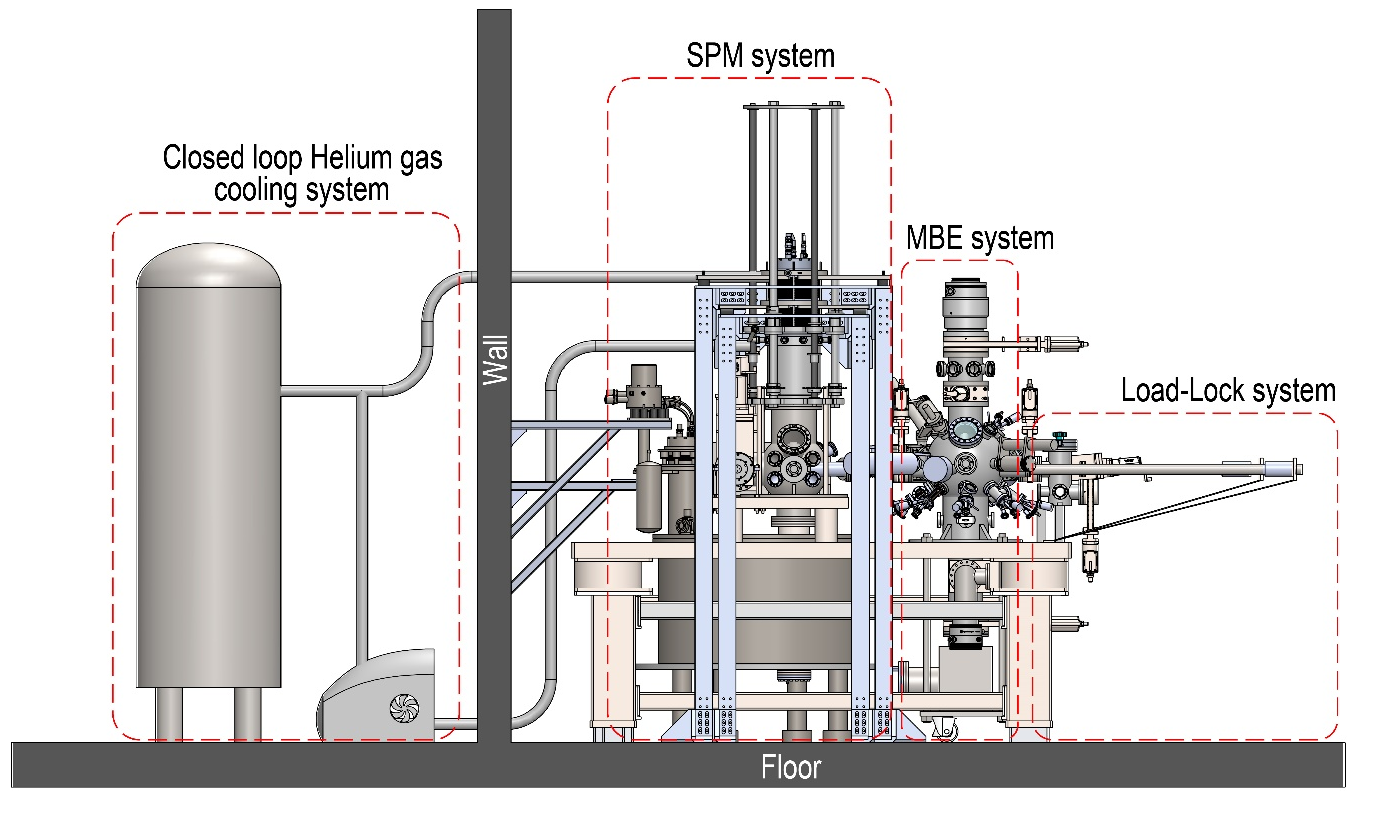

Spin polarized scanning tunneling microscopy (SP-STM) and magnetic exchange force microscopy (MExFM) are powerful tools to characterize spin structure at the atomic scale of conductors and insulators, respectively. For low temperature measurements, liquid helium cooling is commonly used, which has the advantage of generating low noise but has the disadvantage of having difficulties in carrying out measurements with long durations at low temperatures and measurements with a wide temperature range. Therefore, it is quite difficulty to investigate the evolution of spin structures during metal-insulator phase transitions of quantum materials such as colossal magnetoresistance manganites and high Tc cuprates. To solve these two challenges, we have successfully built a cryogen-free system with both SP-STM and MExFM capabilities based on a quartz tuning fork with the Qplus technique. The system can be operated under a 9 T magnetic field provided by a cryogen-free superconducting magnet and in a wide temperature range between 1.4 K and 300 K. With the help of our specially designed vibration isolation system, the noise is reduced to an extremely low level of 0.7 pm. The ability of wide-range temperature variation and the combination of SP-STM and MExFM is especially useful for studying the evolution of spin structures during phase transitions, no matter what conducting state the system is in. This work was supported by National Major Scientific Instruments Development Project of National Natural Science Foundation of China.

Reference:

H.M. Huang, M.M. Shuai, Y.L. Yang, R. Song, Y.H. Liao, L.F. Yin*, and J. Shen*, Cryogen free spin polarized scanning tunneling microscopy and magnetic exchange force microscopy with extremely low noise, Rev. Sci. Instrum. 93, 073703 (2022).

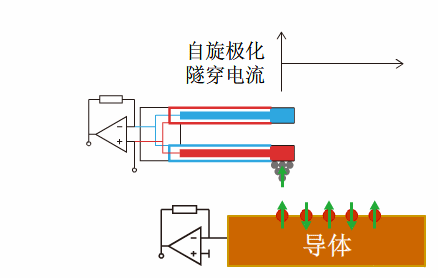

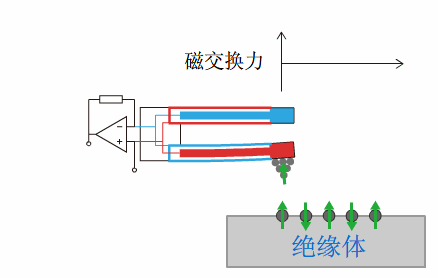

Fig1: The system is in SP-STM mode and MExFM mode, based on a quartz tuning fork with the Qplus technique.

![]()

Fig2: The schematic drawing of cryogen free spin polarized scanning tunneling microscopy and magnetic exchange force microscopy.

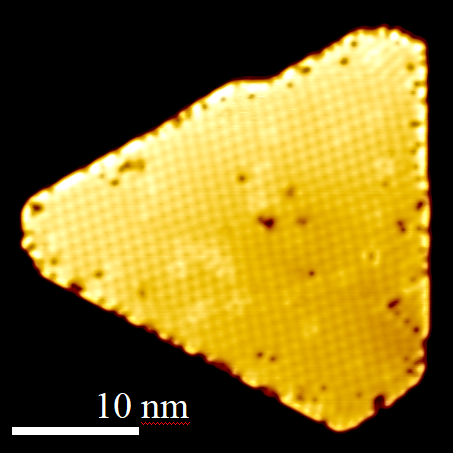

Fig3: SP-STM constant-current image of nano-skyrmion lattice in Fe/Ir(111).

Industrially-scaled large size pulsed laser deposition system

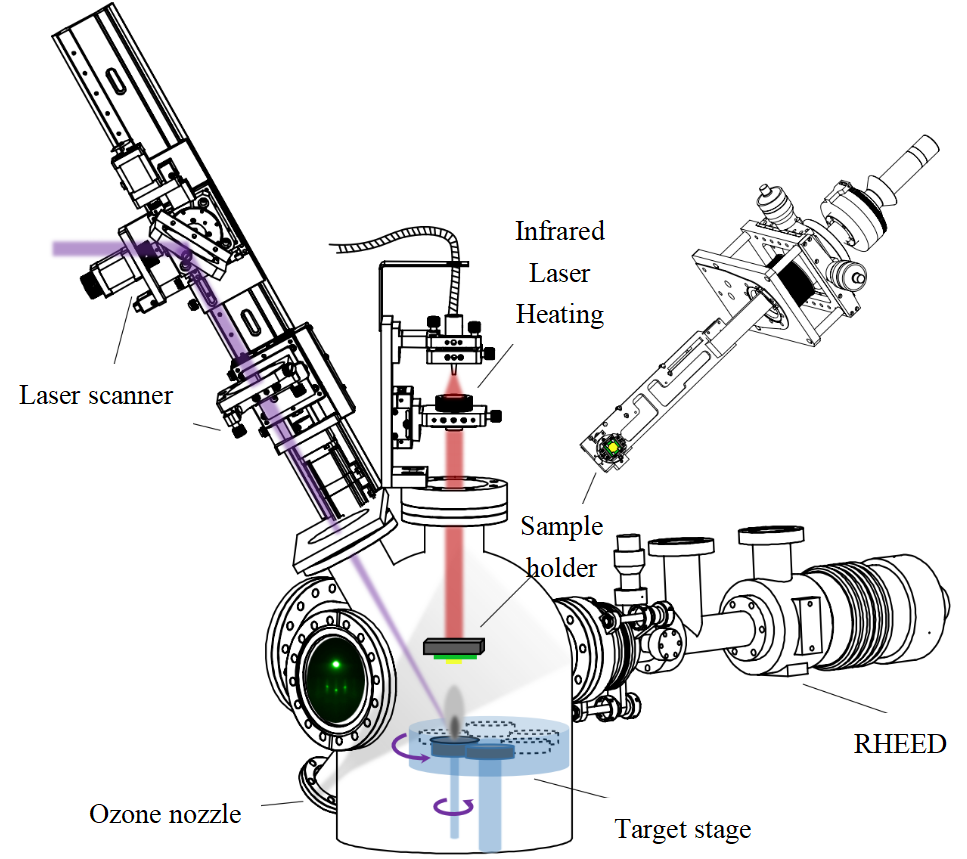

The most common growth technique for complex oxide thin film fabrication is pulsed laser deposition (PLD). However, the sample size prepared by PLD is rather small confined by the plasmon plume. Previous efforts to grow large-sized films with uniform thickness by PLD often moving the substrate while keeping the laser spot fixed. However, the motion of the substrate makes it impossible to monitor the layer-by-layer growth by in situ reflection high-energy electron diffraction (RHEED) intensity oscillations, which is crucial for fabricating high quality superlattices. We design a specifical PLD system that is capable to fabricate large-sized oxides thin films with high uniformity. During growth the laser beam scans the target surface by combining the pitch and yaw angle rotation of the high reflective mirror and the compensated linear motion of focus lens to ensure that the plume energy remains unchanged. A SiC susceptor is placed in between the sample holder and substrate to improve the large area infrared laser heating efficiency. The present PLD system can be used to grow various kinds of complex oxide superlattices with area size as large as 2 inches, which is highly useful for oxide device applications. This work was supported by National Major Scientific Instruments Development Project of National Natural Science Foundation of China.

Reference:

B.Y. Ye, T. Miao, Y. Zhu, H.M. Huang, Y.L. Yang, M.M. Shuai, Z.F. Zhu, H.W. Guo, W.B. Wang, Y.Y. Zhu*, L.F. Yin*, J. Shen*, Pulsed laser deposition of large-sized superlattice films with high uniformity, Rev. Sci. Instrum. 92, 113906 (2021).

Fig1: The schematic drawing of the large size PLD system.